Enriches their ERP with additional location data

Optimizing the usage of AB InBev's trailer fleet

AB InBev, the world’s largest brewery headquartered in Belgium, renowned for its diverse portfolio of over five hundred beer brands including Budweiser, Corona, and Jupiler, partnered with Sensolus to optimize trailer usage, digitize yard management and enhance subcontractor compliance. Within four months, they achieved a 15% optimization in trailer fleet usage.

To achieve this, AB InBev integrated Sensolus’ asset tracking solution into their existing analytics environment. Initially, they utilized the solution to monitor crucial supply chain Key Performance Indicators (KPIs) such as trailer rotation.

Expanding its functionality, they integrated shipping information, enabling real-time insights into product distribution and more accurate lead time estimations.

By leveraging historical and real-time data, AB InBev gained visibility into shipment statuses, enabling informed operational decisions based on actual delivery times rather than estimated schedules. This facilitated optimized delivery routes, real-time ETA monitoring, and a proactive approach to handling delays.

In summary, here is what AB InBev achieved:

- Optimized delivery routes

- ETA monitoring, based on real time information

- Proactive approach to delays

Digitizing yard management & trailer tracking

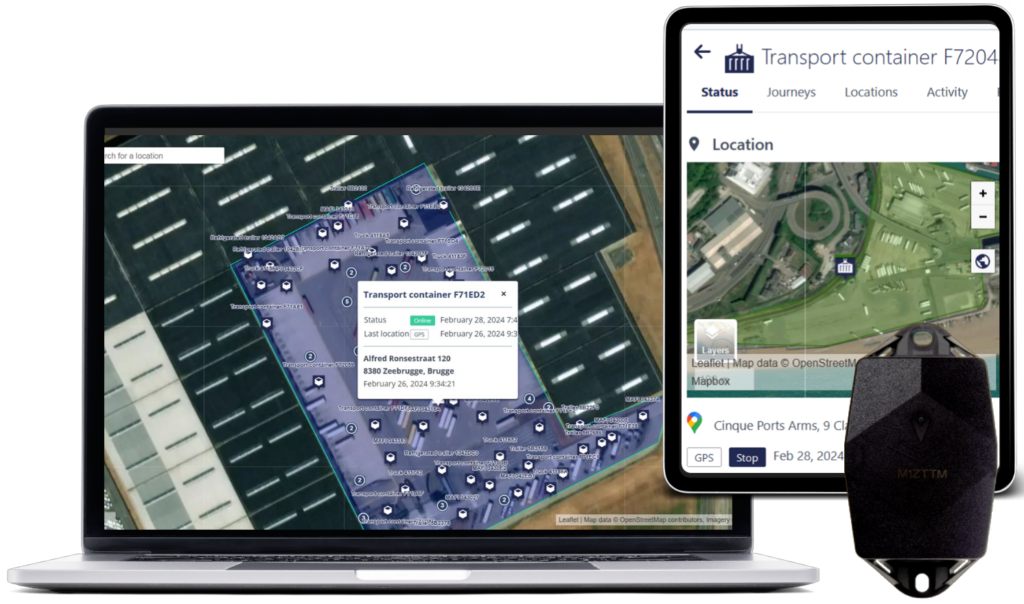

Digitizing yard management was another significant improvement. Previously reliant on manual processes, AB InBev now benefits from increased GPS accuracy, ensuring smoother and more precise trailer collection and delivery, reducing search times and minimizing human errors.

- Smooth & accurate delivery and collection based on location data

- Reduce search times of trailers, relying on maps instead of manual searching

- Avoiding human error in collections by ensuring the correct trailer is collected in the right parking spot

Enforcing sub-contractor accountability

Furthermore, Sensolus’ tracking technology has significantly strengthened third-party accountability for AB InBev. Previously, maintaining visibility into trailer movements during transit and identifying prolonged stationary periods in unauthorized areas posed challenges.

However, with Sensolus’ solution, AB InBev now has real-time insights into trailer locations and can promptly identify instances of prolonged idleness. Utilizing Sensolus’ dwell time application, AB InBev automates the generation of reports on whether trailers are stationary for too long due to sub-contractor negligence, streamlining operations and enhancing overall accountability.

Why did AB InBev choose Sensolus?

Longest battery life

During the initial stages of our collaboration, AB InBev sought a battery-powered trailer tracking solution, recognizing the nascent stage of IoT technologies. They found that Sensolus offered the most robust product with the longest battery autonomy available in the market.

Professional support

AB InBev valued Sensolus’ professional support and guidance throughout the trial phase, particularly due to the novelty of such solutions to their operations.

Business insights from the Sensolus platform

The intuitive platform provided by Sensolus appealed to AB InBev, offering comprehensive insights into trailer utilization and rotation in a user-friendly manner.

Easy API integration

Integration capability was paramount for AB InBev, and they chose Sensolus for its seamless compatibility with their ERP systems

Before Sensolus

- Congested delivery and pickup areas

- Little visibility of the movement of their subcontractors

- Underutilized trailers transporting the beverages

After Sensolus

- Uncrowded delivery yard

- Automated penalty system for non-compliant subcontractors

- Optimized use of their trailer fleet

- Full visibility of the transportation of their goods during collection and delivery of the berverage stocks

In conclusion, Sensolus empowers companies to intelligently manage and track their assets with energy-efficient, easy-to-install solutions. With Sensolus, AB InBev transformed its operations, overcoming previous challenges of congested delivery areas, limited subcontractor visibility, and underutilized trailers.