For many transport and logistics companies, non-powered assets are still a blank spot on the otherwise highly digitized map of their processes. This article shows how smart IoT-based tracking technology can help.

Not only to make non-powered assets visible in the digital world but also to make connected processes significantly more efficient and therefore save high costs.

Knowing where trailers, containers, and other essential assets are located is critical for companies in the transport and logistics industry. Without the ability to monitor their location, it is a difficult task to manage upcoming orders and demand.

Transport and logistics companies need reliable data about the movement, use, availability, and condition of these assets to secure planned transports, optimize their use, and keep losses (including theft) as low as possible.

While the localization and tracking of powered assets can be done relatively easily by GPS trackers because their power supply is guaranteed – the tracking of non-powered assets, such as containers and similar is still a challenge for logistics and transport companies that haven’t digitized their fleets.

That is why it is not uncommon for employees to reach out to colleagues at other locations, cooperation partners, and customers to find out if these assets have arrived or not, whether they are still being used, or where exactly they are on site.

As a result, data on logistical assets need to be managed more efficiently, and digitization is the answer. Preventing human error is one of the main reasons for that.

For example, if an employee forgets to log the change of location, it can take months before this is noticed and the search for the assets’ whereabouts can begin.

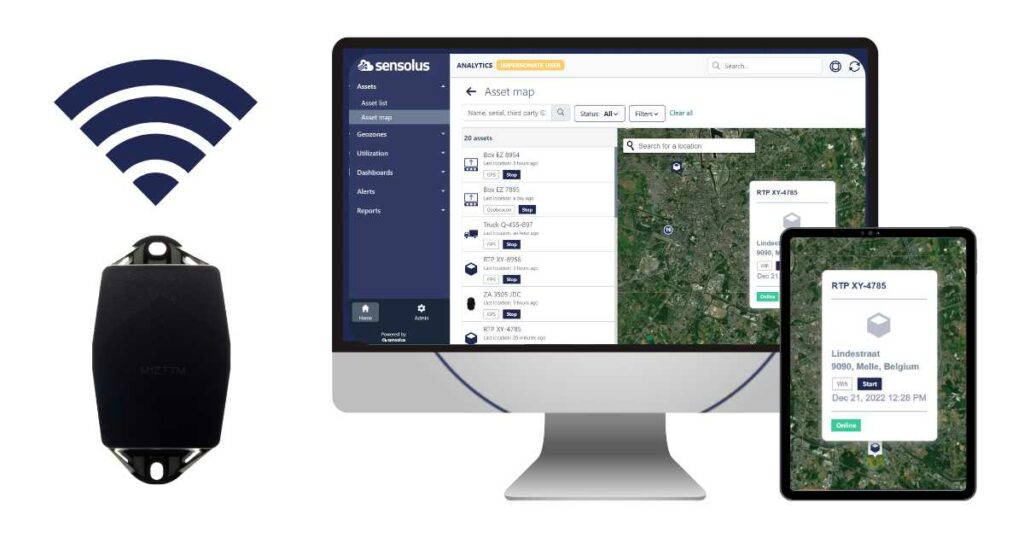

A new generation of robust and battery-powered trackers combined with an intuitive cloud platform can now help to eliminate the blank spots on the map and bring non-powered assets into the digital world. In this way, logistical processes can be planned more reliably and be optimized even further.

Energy for long-lasting IoT connectivity

To make it worthwhile for transport companies to fit hundreds or thousands of non-powered assets with trackers, it must be ensured that their batteries will not run out after a short time.

Otherwise, replacing the trackers would create an expense that would directly reduce any potential efficiency gains. For best results, companies should be able to calculate a battery life of at least five years for their fitted trackers. Depending on the individual use case, choosing the right mobile technology or a combination of different technologies to prevent localization failures can help.

NarrowBand-IoT (NB-IoT), for instance, is a global standard that is recommended wherever energy consumption, building penetration, battery life, and – above all – costs are significant.

In addition, it is also important that the trackers are configured in such a way that they send their data – securely encrypted – only when necessary to ensure efficient management.

Hardshell – sensitive core: sensors for environmental data

Assets in logistics and transport are exposed to harsh conditions. The same applies to the trackers: They have to withstand a wide variety of weather conditions – heat and cold, wet and dry – and therefore have to be as robust as possible.

But smart trackers do not just have a hard shell; they can also be equipped with sensitive sensors that measure environmental data and send it to the management platform. This allows companies to record and monitor critical factors such as temperature (for example to monitor a refrigerated charge) humidity or even tipping movements, such as those that occur when a container is emptied. The management platform can then report an exceedance of the desired limit values via an alarm message and – If necessary – take immediate action.

Powerful analysis and countable benefits

A central cloud-based management platform brings all the data together: It displays a digital twin of each asset on a map and supports the evaluation of tracker data through AI-supported analysis, for example.

This gives managers valuable insights into inventory management, workflows, capacity utilization, and condition monitoring. The result: processes can be designed and optimized a lot more efficiently.

Feedback from Sensolus customers shows how transport and logistics companies benefit from the use of modern IoT tracking technology. They have been able to reduce their fleet asset losses by up to 90 percent, increase their trailer utilization by 5 percent and comply with prescribed transport conditions more easily.