Industrial manufacturing

Track assets in your supply chain.

Digitize your supply chain

We offer end-to-end optimization.

When using Sensolus as your tracking solution, you can have peace of mind that there are no blind spots in your supply chain, delays in production or missing assets.

We help you digitize your non-powered assets including RTPs, containers, boxes, etc., giving you the power to streamline your operations, save costs, and increase compliance.

Enjoy the cost-reducing benefits

It's more than just a tracking solution, we offer a tangible return on investment.

To better understand the value of investing in a tracking system with AI-driven data analytics software, we analyzed a business case of a company that deploys 1.000 tracking units.

Companies that trust Sensolus

Full visibility of your logistics flows

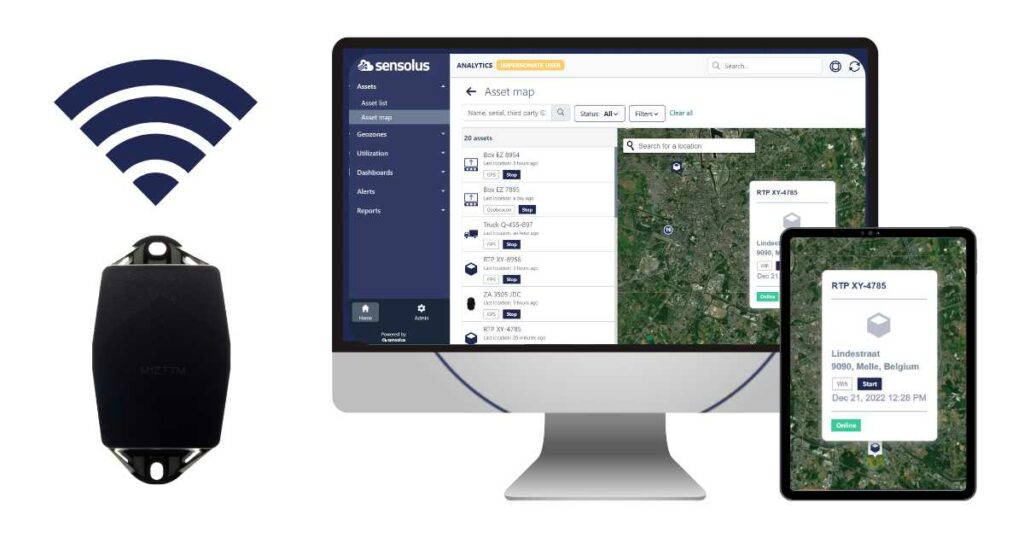

Our responsive platform gives you the control you need.

Connecting these assets to the internet enables you to know where specific assets are, detect issues in your processes and ensure full visibility when working with contractors or customers. You access the collected data on our powerful analytical platform, which is ready to use from day one.

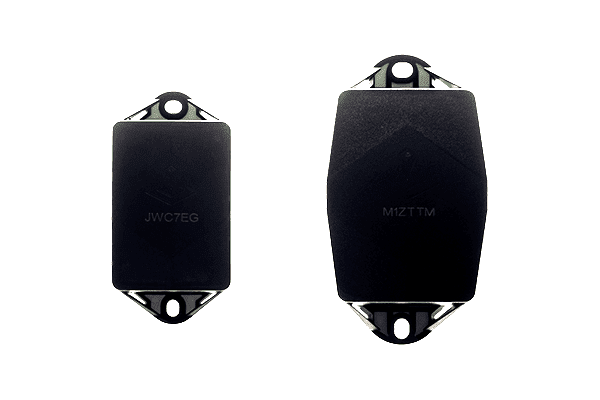

The battery-powered trackers are easy to install and will work anywhere for five years. They don’t require any infrastructure and you can easily scale from a small proof of concept to a fully sized project.

Have a complete view of your supply chain and be alerted when there is an anomaly

Configure our solution to solve daily challenges.

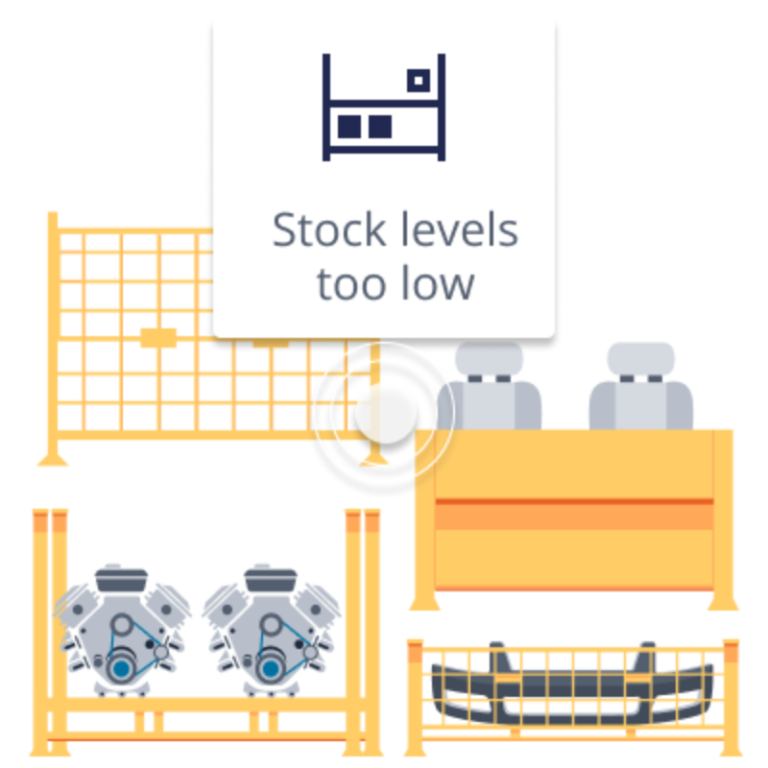

Inventory management

Always know where your assets are, how stock levels are evolving, and more.

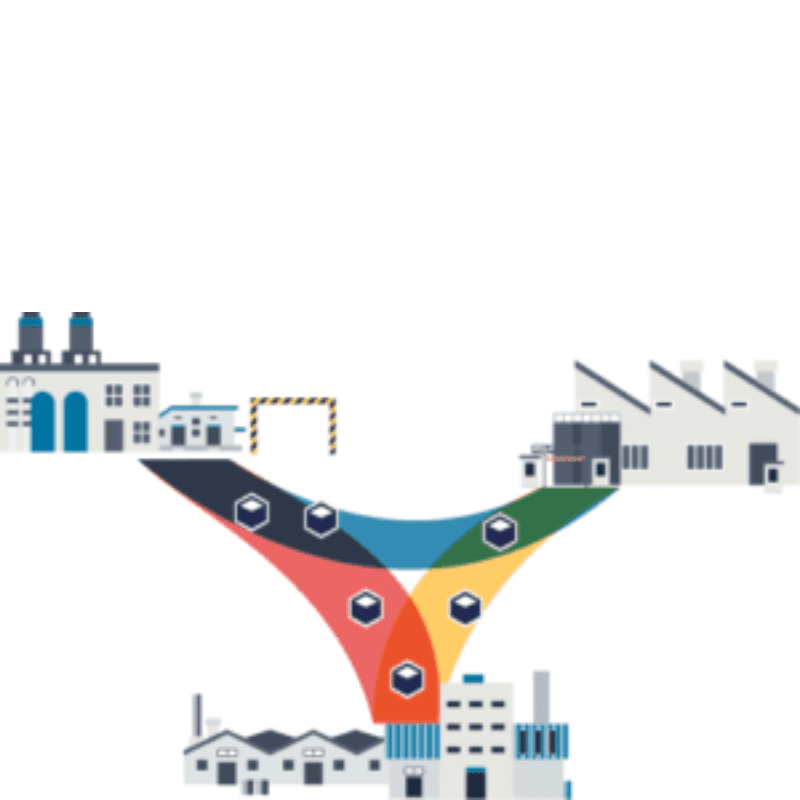

Process flow management

Analyse how assets move between sites, and detect slowing or blocked processes.

Condition monitoring

Depending on the use case, transport assets at the right temperature, humidity, and orientation etc.

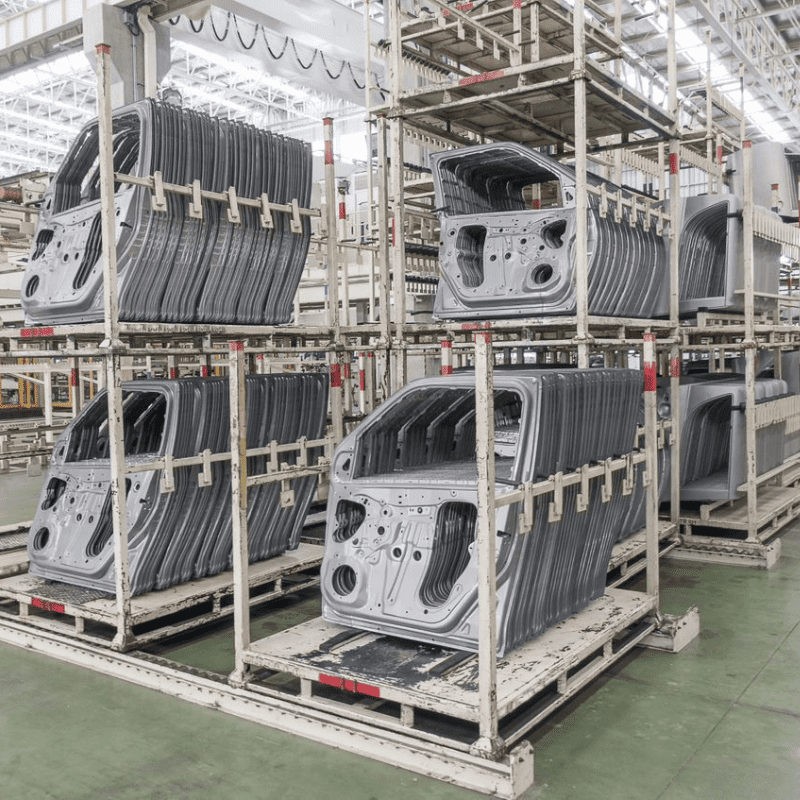

Popular assets to track

RTPs

Stillages and JIGS

Boxes and Pallets

Success stories & partnerships

Sensolus Empowers Airbus with Advanced IoT Technology for Enhanced Manufacturing Efficiency [2024]

In a rapidly changing aviation landscape, where market needs and customer expectations demand the highest standards of quality and performance, Airbus spares no efforts to continuously improve its industrial system. With the Industry 4.0 revolution paving the way for digital transformation, Sensolus, a leading Internet of Things (IoT) technology provider, was selected by Airbus to help them achieve higher visibility, optimization, and efficiency in their smart supply chain and manufacturing processes.

Supply Chain Visibility with Sensolus: The Manufact Scenario

In today’s rapidly evolving industrial landscape, companies like *Manufact face the challenge of efficiently managing their intricate supply chains. The story of Manufact, is a typical …

Supply chain optimization: How to calculate your ROI

Supply chain activities are crucial for industries like automotive, aerospace (e.g., Airbus), machinery (e.g., Atlas Copco), and other manufacturing companies of (large) machinery, vehicles, and …