Supply chain activities are crucial for industries like automotive, aerospace (e.g., Airbus), machinery (e.g., Atlas Copco), and other manufacturing companies of (large) machinery, vehicles, and high-value components.

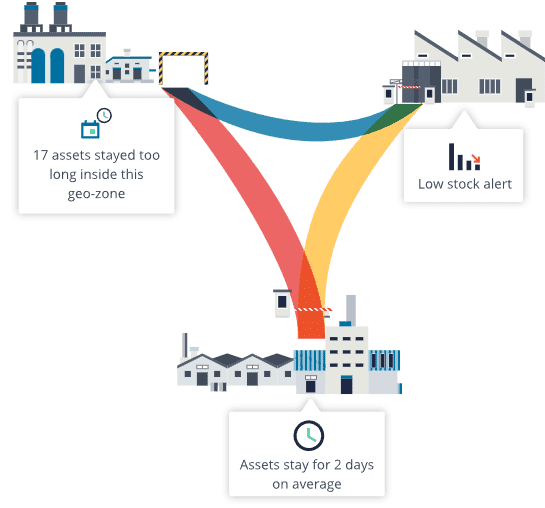

Because they use different transport containers between production facilities, suppliers, subcontractors, or other assembly lines, their operational flows are complex.

Like the domino effect, even one delay has a significant impact, delaying or even stopping the entire production line.

The production parts are usually transported in specific containers. These containers, called “Returnable Transport Packaging” or RTP, often travel in loops, returning to the point of origin to transport a new component.

The cost of an RTP goes from hundreds to thousands of Euros. However, its value goes beyond the container itself.

RTPs can (and should) be seen as more than physical items with just one purpose to transfer parts from one place to another. If you shift your perspective, you will see they are a great source of information, leading you to the right answers.

One solution is to connect your RTPs to the internet and manage them in a unified and scalable cloud-based platform that provides asset visibility, automated inventory management, and analytics. When you track and analyze the flow and conditions of your assets, a wide range of benefits occurs, ensuring a high return on investment.

You can accomplish financial gains in 2 ways:

Interesting to see how many challenges can be solved by utilizing the “hidden” power of your assets’ data.

To better understand the value of investing in a tracking system with AI-driven data analytics software, we analyzed a business case of a fictional company that deploys 1.000 tracking units. All the calculations are based on the information and feedback received from our customers.