In today’s rapidly evolving industrial landscape, companies like *Manufact face the challenge of efficiently managing their intricate supply chains. The story of Manufact, is a typical scenario of an industrial manufacturing company specializing in diverse machine types that relies heavily on a network of suppliers scattered across Europe. The materials sourced from these suppliers are crucial for assembling their machines, which are subsequently distributed to customers. This complex web of logistical flows involves various returnable transport packaging (RTP) types. Until recently, tracking these non-powered assets was a significant challenge. However, the introduction of Sensolus’ tracking solution has transformed their supply chain management, providing visibility and control.

The supply chain of Manufact: a complex web

Manufact operates several factories that produce various types of machines, all dependent on different suppliers for core machine components. These suppliers deliver their parts to Manufact’s main warehouse in Germany. Once the parts arrive at the warehouse, they are distributed to the relevant factories for assembly. After assembly, the machines return to the main warehouse before being shipped to customers.

Challenges in the supply chain

The implementation of Sensolus aims to resolve significant challenges faced by Manufact:

- Eliminate time-consuming searches: The need for manual tracking and searching for transport packages is eliminated, saving time and resources.

- Detect idle assets: Sensolus helps detect idle or underused transport packages, optimizing asset utilization.

- Reduce work-in-progress time: By tracking assets, work in progress of the assembled machines is reduced, leading to more efficient operations.

- Ensure compliance: Sensolus ensures that transport conditions are compliant with specific requirements, enhancing product quality.

- Guard stock levels: Sensolus enables better management of stock levels for transport packages, preventing shortages or excess inventory.

- Improve customer and supplier support: The system enhances the ability to respond effectively to customer and supplier inquiries, improving overall service quality.

The tracking solution in action

With Sensolus, Manufact creates a digital twin for each returnable package by attaching a tracking device to all RTPs, including stillages, jigs, cool boxes, and more. These packages are instrumental in their supply chain operations and monitoring them is key to achieving efficiency.

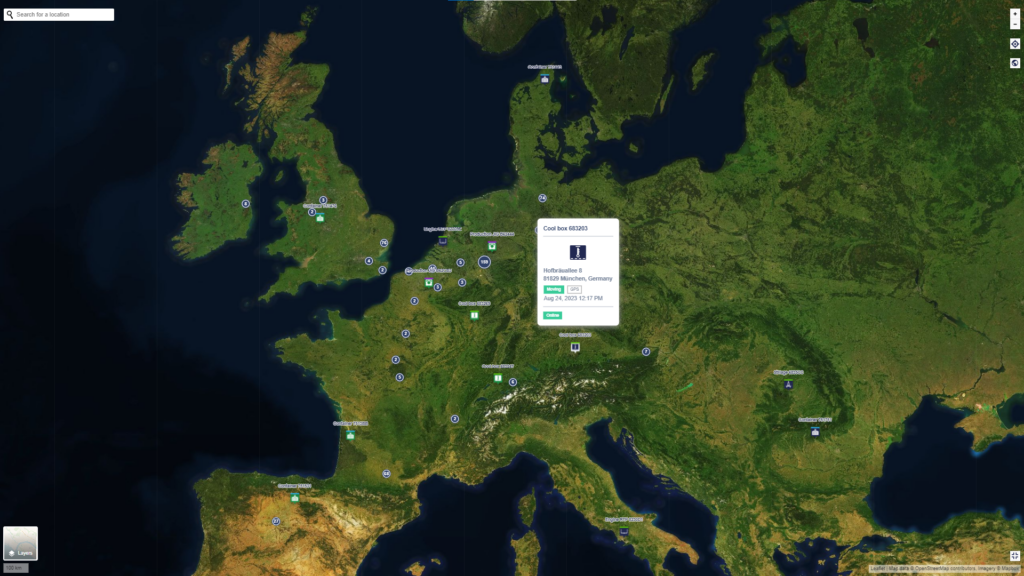

Below is a birds-eye perspective of all these connected assets and where they are currently located throughout Europe.

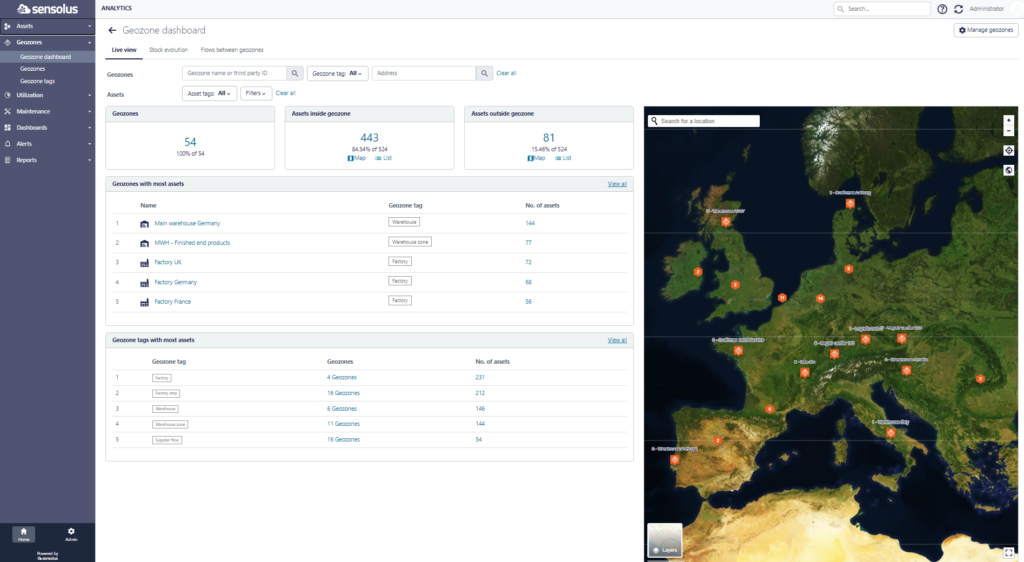

Stock management: Jamie was able to highlight and monitor Manufact’s various sites, including warehouses, factories, repair centres, and suppliers. By monitoring the flow of their assets between these sights and how long they typically remained at each site gave them detailed insights into stock levels, and potential bottlenecks in production.

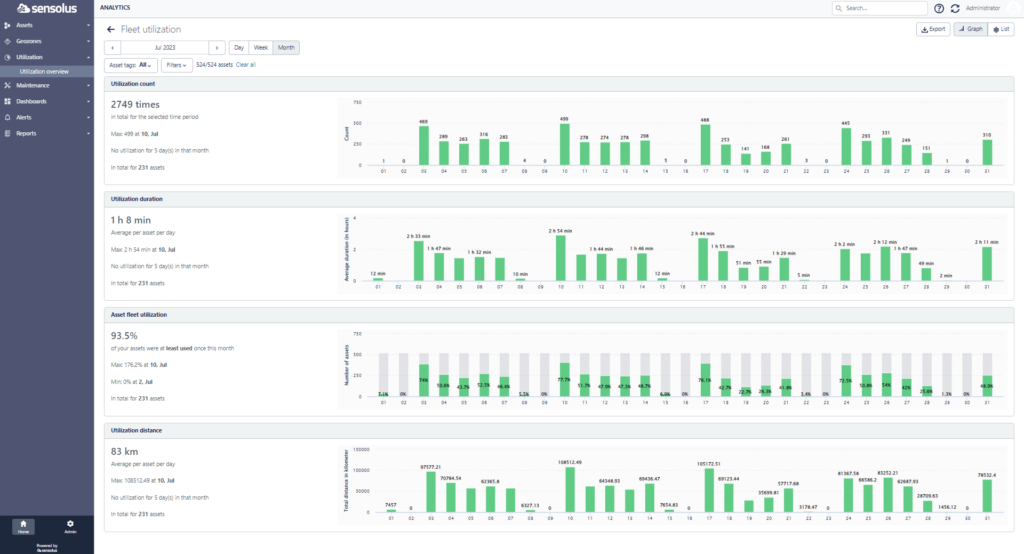

Fleet Management: Previously, Manufact faced challenges in effectively tracking and utilizing their container fleet, resulting in inefficiencies and resource wastage. However, with Sensolus’ technology in place, Manufact achieved over 93% utilization. By continuously monitoring container activity, Manufact was able to identify and address issues promptly. For instance, excess inventory problems that might have gone unnoticed in the past were now easily detectable. The ability to promptly identify such issues allowed Manufact to optimize their inventory management strategies, reducing excess inventory levels and related costs.

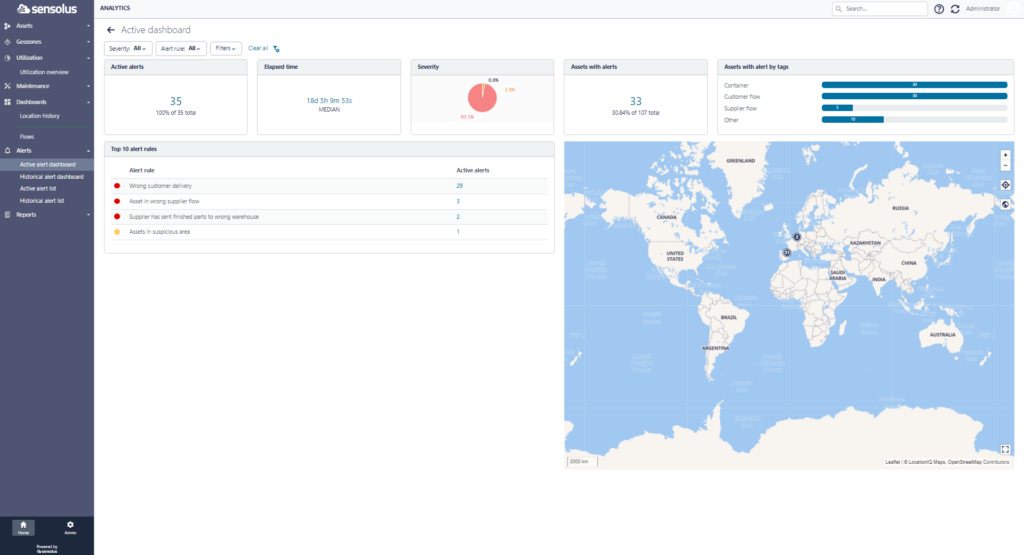

Proactive Alerts: In the past, identifying and rectifying such errors could be a time-consuming and costly process., with Sensolus’s alert system in place, Jamie received immediate notifications whenever a wrong delivery occurred. This meant that Jamie could address the issue quickly, and the company could also minimize any negative customer impact, preserving their reputation for reliability.

Non-compliant third-party involvement was another area where proactive alerts proved invaluable. Jamie could now receive alerts the moment any third-party or external entity deviated from the established compliance standards. Whether it was a contracted logistics partner not adhering to specific protocols or a vendor not meeting agreed-upon terms, the proactive alerts allowed Jamie to intervene promptly.

Additionally, Sensolus’s alert system facilitated the rapid identification of assets in the wrong location. In industries where assets are constantly on the move, misplacements or unauthorized movements can have significant repercussions. With the alert system in place, Jamie was instantly notified whenever an asset was detected in an unexpected or unauthorized area. This proactive approach enabled swift actions to correct the situation, preventing potential losses or security breaches.

Achieving remarkable results

The implementation of Sensolus brought about remarkable changes:

Like most companies that integrate Sensolus, Manufact’s losses were slashed by an impressive 80%, translating into substantial cost savings. Operations achieved peak efficiency as work in progress for assembled machines was significantly reduced. Compliance monitoring was streamlined, guaranteeing that goods consistently met necessary conditions during transport. Optimal stock management was achieved, effectively preventing shortages and excess inventory. Additionally, the system enhanced customer and supplier support, facilitating quick, informed responses and elevating overall service quality.

In conclusion

By providing visibility, proactive alerts, and actionable insights, Sensolus has empowered Manufact to overcome its logistical challenges and pave the way for a more efficient and responsive supply chain.

Jamie and the team at Manufact now enjoy a supply chain that’s efficient, compliant, and customer-focused, thanks to Sensolus. Their story stands as an example of how Sensolus has helped companies transform their operations within the industrial manufacturing sector.

*Manufact is a fictional use case created using an aggregation of data and testimonials gathered from active customers, to serve as a practical example of the benefits of Sensolus.