Since 2013, the Sensolus team has been involved with a large number of international digitization projects in industry, specific to non-powered assets in the supply chain such as transport packaging, stillages, containers, equipment, etc.

Based on insights we have gained over the past decade, I have realized 5 supply chain predictions for 2023, and we anticipate the industry will reach unprecedented heights as these predictions take hold.

In summary, here is what you can expect:

- Supply chain digitization is the new normal

- Compliance drives investments

- Process intelligence is the next value wave

- Technology maturation and standardization

- Corporate responsibility drives asset and process digitization.

Prediction 1: Supply chain digitization is the new normal

It has become apparent that recent global economic changes are fueling the adoption of digitization within the supply chain. In 2020, the Covid pandemic caused a shockwave in global supply chain processes. In 2022, war, the ongoing energy crisis, and the inflation of commodity prices have accelerated the need for data-driven insights into the supply chain.

2023 will not be different, industries are integrating digitization into their processes as the economic value drivers can’t be ignored. Digitization is a cost-saver, increases daily productivity, and provides more visibility and transparency to all stakeholders.

There is a general awareness that supply chain digitization is the new normal. Like how phones, PCs, printers, internet, laptops, and smartphones have been adopted, IoT in non-powered assets will be normal soon. And those not stepping in will lose market share and competitiveness.

Supply chain digitization is a strategic asset for all industries, and according to Gartner, the supply chain was halfway there in 2020, we can expect the numbers to be higher in 2023.

Prediction 2: Compliance drives investments

As our regulatory and contractual environments become increasingly complex, my second prediction is that “compliance” will push more businesses to invest in digitizing non-powered assets. In all industries that we serve, industry leaders want to ensure they are compliant with the promises they make to their customers and stakeholders.

Some of these promises are legally inspired, such as temperature control on perishable goods, food, and pharmaceutical products, or multi-modal logistic logbooks for dangerous goods transport.

Many are contractually inspired, such as conditioning monitoring (shock/tilt) during transport, the timely delivery of goods at locations where suppliers have no access, ensuring buffer stocks of packaging to avoid penalties, or providing digital location logbooks for insurance purposes.

Without any intention of a negative connotation, the industry leaders are investing to carve out the “loose ends” in their processes by digitizing the non-powered assets. They all strive for end-to-end process control and compliance.

Dun & Bradstreet conducted a sentiment report surveying 600+ compliance and procurement professionals, they listed supplier monitoring as a key component of a risk-based program.

Prediction 3: Process intelligence is the next value wave

The era of “process intelligence” is the core value driver for industries wanting to embrace the Internet of Things technology in their processes.

In 2015, IoT companies primarily focused on “connecting non-powered assets” and creating “digital twins” of these individual assets in a scalable, reliable, and efficient way.

Digitization empowers the supply chain industry to effectively control these assets without the danger of blind spots and human error that come with outdated, manual logging.

In 2019, the focus was shifted towards “connected processes”, i.e., getting visibility on the processes that rely on non-powered assets.

For example, by integrating connected processes, industrial equipment manufacturers gain visibility on the performance of their packaging flows (KPIs), visibility on the retention and rotation of their packaging, and receive notifications if deviations occur.

As more assets become connected, processes become more visible, and process intelligence can finally flourish.

In essence, the data collected around these “assets” and “processes” will ultimately fuel actionable insights that will optimize processes and transform businesses.

IoT has become a crucial ingredient used by analyst teams (and AI platforms) to detect patterns, forecast improvements, and invest in change, which will have a long-term strategic impact on these industries.

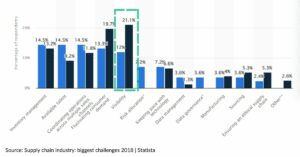

As seen in the graph below, Statistica has indicated in 2018 already that visibility is at the top of the list as one of the biggest challenges that the supply chain faces. This is a clear indication that this industry has shifted towards addressing this problem in the following years.

Prediction 4: Technology maturation and standardization

My fourth prediction is a technology-driven one. During conversations and workshops with the Sensolus team, I often refer to the “jungle of IoT” because IoT technology has many different hardware providers, communication protocols, localization technologies, upcoming inventions such as energy harvesting, satellite communications, blockchains, and so much more.

IoT technology is constantly evolving, and customers can easily get lost in this “jungle,” not to mention the many dangers of investing in the wrong technology, which is required to operate for many years. Sensolus eliminated these worries for all its customers because we offer end-2-end accountability. Sensolus is a one-stop shop in that regard. Sensolus eliminates these worries by offering end-to-end accountability and a function as a one-stop shop.

But let us not forget, 2023 is about more than just technology! Standardization and maturation are kicking in, with examples such as low-power cellular connectivity, Bluetooth as an industry standard, proven hardware will be available in volume, and so much more. The industry decision criteria have shifted beyond implementation, rather towards the long-term reliability of the technology, i.e., proven OEM liability, hardware supply chain continuity, cyber security readiness, connectivity flexibility (no single vendor lock-ins anymore), guaranteed life-cycle management, etc.

With the large-scale adoption of IoT, there is a strong focus on long-term operational risk reduction in its selection of partners.

Personally, I´m also a bit of a tech junkie, but our industry is no longer about “innovation,” it is driven by “operational excellence and execution,” or as we like to put it “It just works!”

Prediction 5: Corporate responsibility drives asset and process digitization

My final prediction of 2023 is probably more of an annual wish for the year than a prediction. We all have a long-term, life-threatening challenge in front of us: climate change. This one will make the recent pandemic and economic hiccups feel like small wrinkles in a global shake-up.

Digitization contributes significantly to our transition towards “doing more with less.” By creating digital twins of non-powered assets and generating process intelligence, we have the data and intelligence to reduce our environmental impact significantly.

According to research by Gartner, only 15% of the respondents don’t have plans to invest in IoT as a technology to enable circular economy activities.

Going green with packaging and transportation is easier than you think! For starters, single-use packaging can be replaced with reusable options made from recycled plastics. Additionally, multi-modal logistics (including less polluting transportation means), asset loss prevention, and a circular economy implementing sharing of non-powered assets like containers or pallets offer great potential to reduce our global waste footprint.

We all have a common challenge, and asset digitization is certainly an innovation that can drive part of the transition. In 2023, when many economic challenges will be present in all industries, corporate responsibility will undeniably influence decision-making, and make a significant and positive impact in the long run.

About the author, Kristoff Van Rattinghe

Kristoff is CEO and co-founder of Sensolus. Since its foundation, Kristoff has built up in-depth knowledge about transport and logistics chains. He understands better than anyone how the Internet of Things offers a solution to various challenges in the industry and how companies can ultimately save (a lot of) money.

Before Sensolus, Kristoff has built up a track record in setting up new business units, building project teams and successfully translating ideas into product in the ICT sector. In addition, Kristoff, as a board and unit manager, has provided important added value in the marketing of software applications for renewable energy.