Written by Kristoff Van Rattinghe, CEO and co-founder of Sensolus

Sensolus was founded in 2013, with the vision of digitizing non-powered assets on an industrial level. Our mission is to connect transport packaging, pallets, storage boxes, containers, stillages, and numerous other industrial assets to a cloud-based platform. Once these assets are connected (we call it a digital twin), there is the opportunity to completely optimize operational processes across the board.

By creating a digital twin of non-powered assets, the return on investment seems to be obvious – companies can automate inventory management, make sure they are in the right place at the right time, streamline transportation, and create efficient maintenance programs, to mention a few. You can even achieve new revenue models by pivoting towards a “pay-per-use” business model.

When looking at all these benefits, the mass adoption of the industry of things (IoT) is a no-brainer, right?

Is this what industry has been waiting for, are we prepared for the impact?

When taking a step back, it is easy to see why the hyper-scale has less “hype” than anticipated…

Here is why industry is only starting to get ready for change:

The impact is big, but so is the risk

In sales, our ideal scenario is where a decision-maker has one pain-point that we can resolve.

For example, a supply chain manager manages 200 unique transport boxes and he loses 10% of them each year, bear in mind these boxes are often quite expensive, so not only does he lose inventory, but money is also wasted, and production delays are inevitable. Our solution is clearly the answer to this well-defined challenge.

But in reality, a tracking solution impacts an organization at its core. The real value comes when all transport boxes are connected at all different locations (and not only the 200 expensive unique ones). This level of interconnectivity allows the company to optimize and refine all related processes (inventory, logistics, replacement, maintenance, invoicing, customer service, etc.), generate actionable insights and process intelligence.

You can imagine, as IoT becomes a core operational driver, massive opportunities are suddenly created, but also strong dependency and technical constraints, which come with risks and uncertainties.

Compare this to the introduction of an ERP system, migrating an entire company’s data into the cloud, or offshoring your IT and customer service department. IoT is not different, the impact is big, but so is the risk.

So, what blocks the decisions?

When we look at the big picture, digitizing non-powered assets is clear, but industry buyers still come with objections to this massive roll-out.

Let us list the 5 most important ones we face:

Objection 1: It´s not yet a technology standard

A long time ago, some of you probably bought a “Betamax” video player or a “Sony Minidisc audio system”. Both are very promising technologies, but they did not become the standard. It is typical when new technologies emerge to see alternatives come up – some of these technologies will become a standard, while others will die over time.

The Internet of Things is not very different. In the last 10 years, numerous technologies have popped up, each one fighting for eternal fame. However, in the last 3 years, standardization in IoT is becoming more apparent.

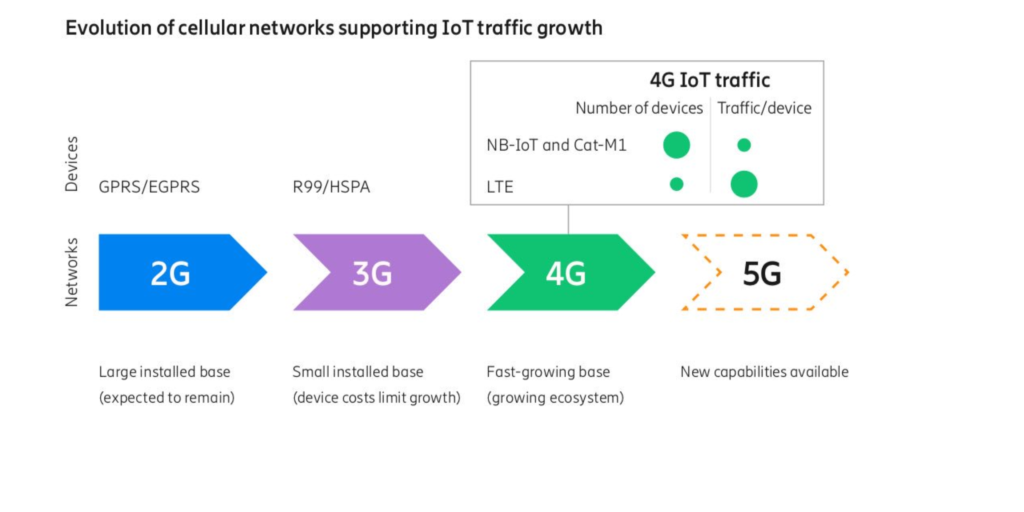

GPS, BLE (Bluetooth Low Energy), and Wi-Fi have become standards in our industry for low-power localization, while REST API and MQTT are the standards for sharing data between IT platforms. Similarly, we see that cellular low-power connectivity (NBIoT and LTE-m) is stepping up to become the standard in radio-based public networks (as they are globally adopted in the 4G/5G standard).

Are these the best technologies for our industries?

As a true engineer, I need to admit they are not the best, like Minidisc is technically better than MP3. There is no one size fits all technology, each with its strengths and weaknesses.

Standardization provides the buyer with the “power” to compare offers, negotiate communication contracts, have multiple providers (at a lower cost or higher service quality) for future operations, and certainly have fallback options if things change over time.

Standards are thus insurance for the buyer and thus crucial for mass adoption.

Objection 2: There might be a next big thing

As we all know, technology evolves incredibly fast, however, adoption is slow to keep up. And as we consider standardization, there is always the possibility of “disruptors”.

For example, in 2021, Apple launched the Airtag for tracking your valuables. By leveraging their massive global presence of smartphones, Apple could easily create a tracking solution in the consumer market which works well. In 2022, Apple passed a whopping 1B$ revenue on these Airtags alone. And honestly, I also have one in my suitcase when traveling.

In parallel, we have all seen the launch of SpaceX’s Starlink satellites on the mission to become the internet provider from space. Surprisingly, they have also filed patents for low-power IoT applications. Will SpaceX become the disruptor in low-power communication networks?

And similarly, we are seeing the first prototypes of IoT sensors with energy harvesting, claiming that they don’t ever need to be charged or require battery replacements, does this mean that the need for sensors with long-term battery life would be a thing of the past? Likely not, since these energy harvesting sensors have not been validated at scale, and relying on an unproven solution is a risk in itself.

We do love these evolutions; they are inspirational to all of us. But will you invest in a solution today that relies solely on proprietary IPs, for example, Apple, Google, and Starlink? It isn’t an easy choice considering that in August of 2022, Google announced to completely stop its IoT core cloud platform. We need to think twice before integrating a technology that needs to run for many years.

Please do not misunderstand me, these evolutions make our sector amazingly interesting, and we follow them closely, but some of them are still too underdeveloped to rely your future processes on it.

Objection 3: It´s too expensive

Well, I´m sure you think right now that this is an obvious objection. Some of the actors in our industry have been pitching extremely low-cost sensors, and even providing communication services at ridiculously low tariffs. In a perfect world, this scenario may have worked if it became an industry standard. But in reality, this is not the case.

In my opinion, this is a twofold challenge: The buyer is not yet ready to adopt this technology, and/or the technology is in a premature phase.

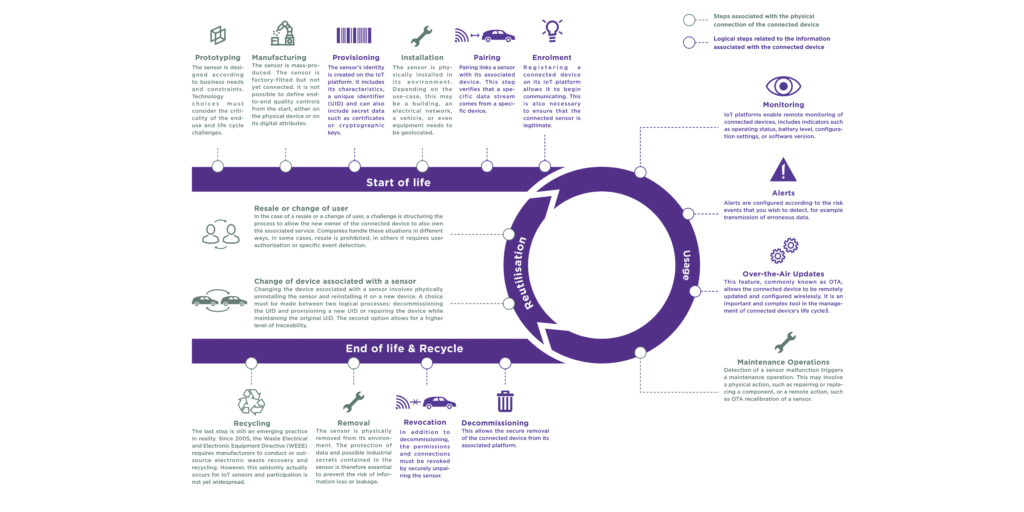

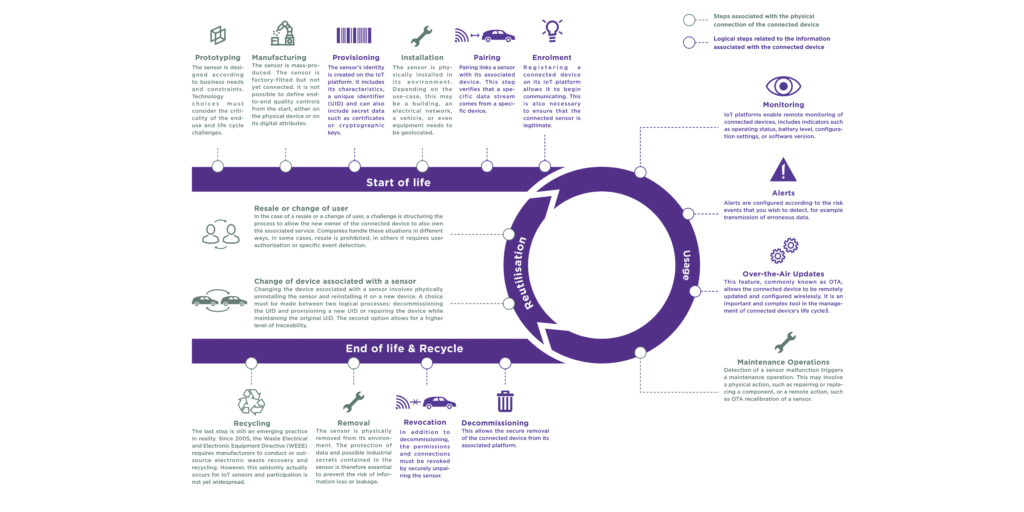

At Sensolus, our role is to educate our buyers. Over the last 10 years, we have learned how to effectively implement IoT into company processes, while consistently validating the different technologies available. In addition, by working with customers over many years, we understand well that the total life-cycle cost should be taken into account. This includes installation, battery replacements, integration into internal systems, data insights training, the adoption of optimized processes, and so much more.

In this context, I strongly believe that having streamlined training for the users, a very efficient installation procedure, and even achieving extra battery life out of each sensor directly compensates for the higher initial investment cost. The difference is that most buyers compare upfront costs, without taking all of these additional variables into consideration from the beginning. We also have seen in our industry that multiple small projects fail to reach maturity, as this life-cycle cost has not been taken into account at the start.

But, let me now jump back to the objection.

At Sensolus, we know the lifetime cost of IoT. And we are experts in what data and insights will be provided to our customers at this cost. In essence, we know the “unit cost” per “relevant business data point” and we have optimized our solution to completely control this cost over the lifetime.

Is this too expensive? For our customers, the value of having this “IoT-provided business data” clearly outweighs the costs, and it is a straightforward investment for them. With this in mind, we know that the current maturation and standardization of IoT technology will lower the “unit cost” and accelerate further mass adoption. We do see what is ahead of us.

Objection 4: What if things go wrong at Sensolus?

Honestly, I believe this is a very valid objection, every CEO can relate.

Running our own company, we ask the same questions when we invest in a new manufacturer, cloud-service provider, or software subcontractor. (Un)Fortunately, we have made mistakes and things went wrong, and things may go wrong in the future, but over the past 10 years, we have evolved, learned, and grown from those mistakes.

Every time we got hit, we took the hit, we solved it, and equally important, we took this opportunity to reflect strategically, and respond with innovation and hard work.

As we have signed multi-year contracts with our customers, we have been forced from day one to stay in control of the lifetime operations. Today this is a given, but many years ago this has been a daily engineering challenge.

Over the years, we always asked ourselves how to minimize our risks and the risk for our customers, and how to bring comfort to our network if things go wrong.

Maybe not my best marketing quote, but we have a customer reference about how we “failed” and “solved it”. This learning resulted in adding step by step new engineering features to our solution, which are currently bundled under life-cycle management.

In essence, today, we provide diagnostics from sensor to application, to remain in control and get early warnings on failures. This is about security, battery performance, sensor settings, firmware updates, network behavior, and so much more. As we signed multi-year contracts with our customers, we have been forced from day one to stay in control of the lifetime operations. Today this is a given, but many years ago this has been a daily engineering challenge.

We also implemented strategic partnerships with manufacturers which allow us to have quality control on every level of electronics, software, and testing – even selecting technology standards at the production level.

This learning curve also resulted in implementing contractual procedures to make our customer’s data available (if Sensolus disappears). Over the years, we always asked ourselves how to minimize our risks and the risk for our customers, and how to bring comfort to our stakeholders if things go wrong. Similarly, as with the technology standard, our buyers need insurance and fallback options if we fail.

Objection 5: We don´t have the manpower

In an instant reply, I used to brag about our technical features such as our plug & play, works out of the box, self-install in 1 minute, but I learned to listen better because it is more complicated than that. Industries already need to cope with pandemics, inflation, supply chain disruptions, geo-political instability, the “great resignation”, and many more factors that will impact the sustainability of their business, which certainly brings additional load on the existing teams.

To make it more complicated, implementing an IoT tracking solution may open a “pandoras box” that cannot be closed. Flaws in operational processes could be revealed that ask additional team effort to resolve. Understandably, this seems like a “no go” for a lot of companies that are already faced with numerous external challenges.

But if this objection comes, the customer is already convinced on the value, but he fears the operational impact and wants to be “unworried” on the unexpected challenges related to implementation, adoption and maintenance.

In essence, this fifth objection is not an objection, it is an invitation to solve it.

In the last 10 years, we discovered that a solution is only a solution, when it really solves the “pain” of the customer, and this is much more than offering a good “core” product.

We have been blessed to work with many different trusted partners in our eco-system, and they have played a crucial role in bringing Sensolus to the level it is today – at all those different geographies and industries. Our value added-resellers, our technology partners, our integration partners, and our network partners, are all essential in supporting the customer with additional services required for the adoption of IoT-driven solutions.

In conclusion – going forward

As CEO, my role is to document and bring an answer to these typical objections, and yes, we do have sales processes in place to support this. But reflecting over the last 10 years:

Our secret ingredient has been “trust” and “transparency”.

We handle our business with care, and we support our partners and customers in their projects with the same care as we apply to our own business. And we would rather openly talk and work on objections than push them away with unrealistic aspirations and promises we cannot hold.

Objections in our business are healthy, they reveal lessons to us and they ensure we question how to do our job better.

The mass adoption of IoT technology comes when you cope with all the possible objections, and with this comes many learnings.

This is a journey, where small steps are equally important to big disruptive jumps.

About the author, Kristoff Van Rattinghe

Kristoff is CEO and co-founder of Sensolus. Since its foundation, Kristoff has built up in-depth knowledge about transport and logistics chains. He understands better than anyone how the Internet of Things offers a solution to various challenges in the industry and how companies can ultimately save (a lot of) money.

Before Sensolus, Kristoff has built up a track record in setting up new business units, building project teams and successfully translating ideas into product in the ICT sector. In addition, Kristoff, as a board and unit manager, has provided important added value in the marketing of software applications for renewable energy.